Your natural path from current operations to humanoid operations through continuous improvement.

You’ve reached full video coverage of this task.

Enough real-world examples are captured to standardize and automate this work. Generate a task model to power onboarding, SOPs, audits, and robot/humanoid execution requirements.

Turn physical work into a searchable system — and a roadmap to automation.

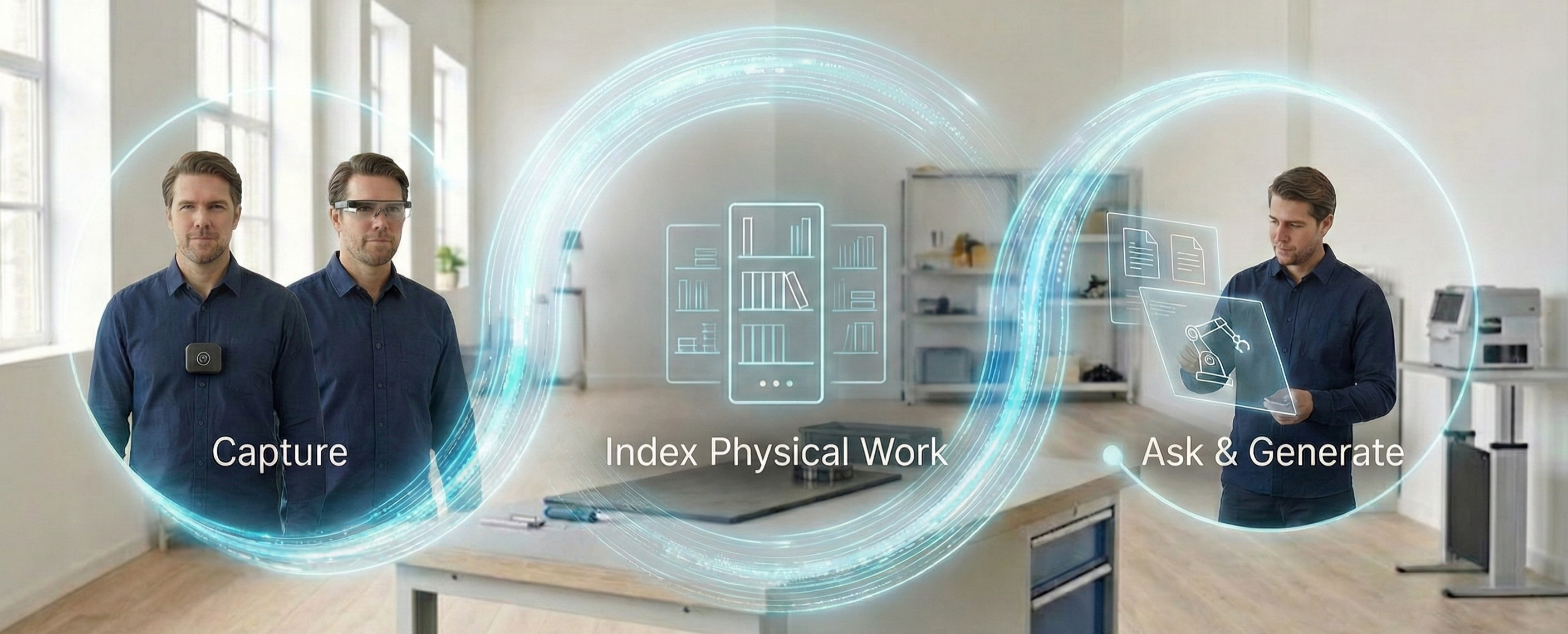

Workcheck captures frontline work via POV video (smart glasses or chest cams), converts it into a structured work index, and lets your team generate SOPs, onboarding, safety improvements, and robot/humanoid requirements.

Get control of the work — without slowing down your best people.

Capture real work once, then reuse it across onboarding, safety, standardization, and automation planning.

Capture what happens on the floor, structure it, then ask anything.

Workers record POV video as they work—no forms, no friction.

Workcheck turns raw video into a structured library: steps, tools, parts, hazards, variations.

Search your operation like a knowledge base—generate documentation, training, and automation specs.

Ask about anything. Get practical outputs.

See how Workcheck turns real work into SOPs, onboarding / training material, safety notes, and automation requirements.

- Step-by-step sequence with time ranges and variations.

- Tooling and setup notes (fixtures, gauges, consumables).

- Quality checkpoints: what to measure + pass/fail criteria.

- Safety notes: hazards + PPE reminders.

Coverage across core manufacturing work

Start with one station or one cell—then scale across your facility.

Designed for real facilities

Practical controls and privacy-by-design options—without slowing down the floor.

Role-based access to recordings and generated outputs.

Face blurring and configurable retention policies.

Cloud best practices for data in transit and at rest.

Pilot Workcheck in one cell, one shift, or one line

Tell us your environment and the work you want to capture. We’ll suggest a pilot plan and what you can automate first.

Ready to pilot Workcheck?

Send a quick note to marcus@humanoidnorge.no with:

- Name

- Jane Doe

- Work email

- jane@company.com

- Facility / focus

- Machine shop · discrete manufacturing · automotive

- First work to capture

- Example: machine tending + QC + changeovers on Line 3

Include any other context that helps us scope your pilot. We’ll respond with a tailored plan, timeline, and what you can automate first.

Built for real floors: high-mix operations, variation, and tight quality constraints.

Start with documentation and onboarding—then move toward robots and humanoids with clear requirements.

Access control, configurable retention, and face blurring when needed.